Investment in Expanding Robotic Welding Capability

Nichol McKay Expands its Robotic Welding Capability for Large Assemblies

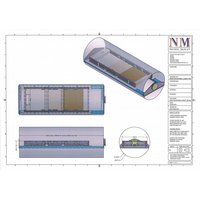

Nichol McKay has invested in expanding the production capability of its largest robotic welding cell. The manipulator table has been completely redesigned to accommodate much larger assemblies such as Chassis and Baseframes and now has a capability to weld assemblies with maximum dimensions of 5.5mtr Long x 1.9mtr Wide x 1mtr High

We are delighted that this capability enhancement will support our ongoing efforts win supply contracts for large fabricated assemblies currently produced in perceived "Low Cost" regions such as China. The automation and labour reductions offered by Nichol McKay's highly developed robotic welding systems can offset the lower labour rates in these regions. Sourcing from Nichol McKay's UK base can also significantly reduce customer lead times and therfore inventory costs and by taking inertia out of extended supply chains, improve our customers agility and response time in the event of design changes, which in turn slashes the risk of obsolescence and rework costs.